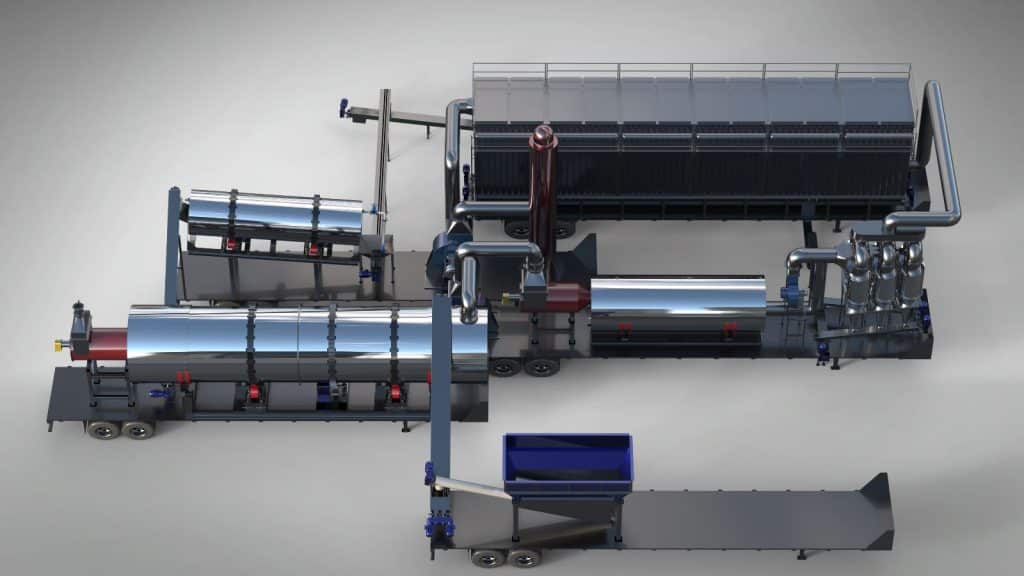

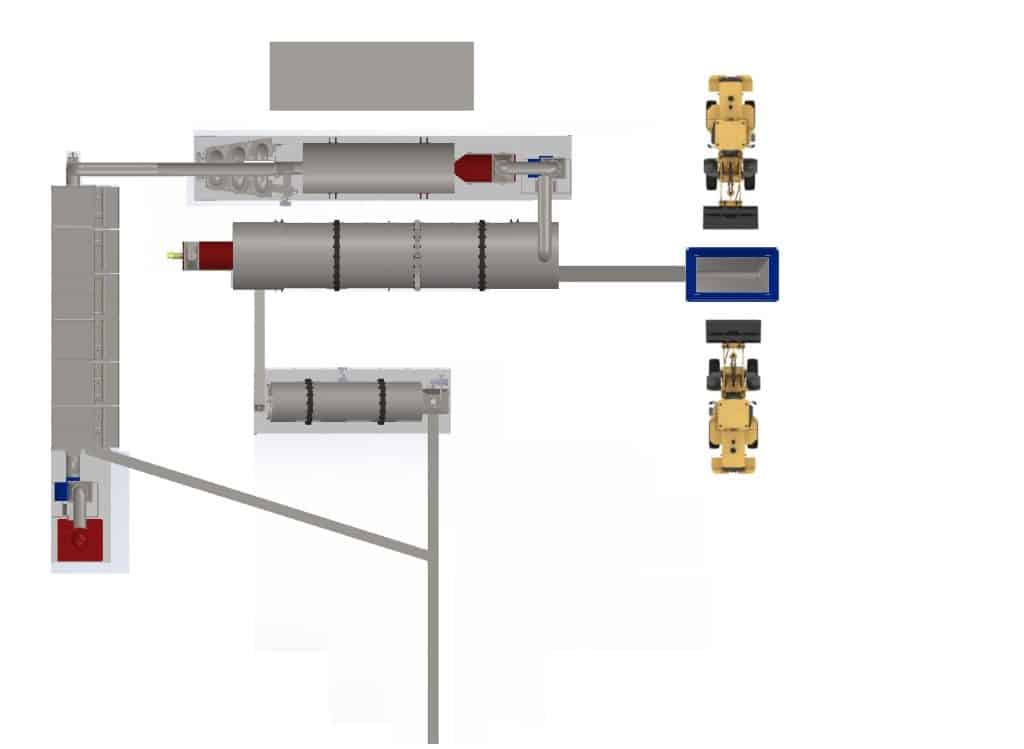

Mobile Direct Fired Thermal Desoprtion Units

Model:DFDY 10-20

Drum Dimensions

Diameter 1.55 Cm x Length 7.50 Cm.

Processing Capacity: 22-33 TPH

Optional Mobile

Model:DFDY 20-40

Drum Dimensions

Diameter 2.20 Cm x Length 12. Cm.

Processing Capacity: 44-55 TPH

Optional Mobille

Model:DFDY 40-60

Drum Dimensions

Diameter 2.50 Cm x Length 21 Cm.

Processing Capacity: 55-110 TPH

Stationary

The treatment process is simple and starts with the feed hopper feeding the soil at the inlet of the unit.

To prepare the soil for cultivation, it is pre-screened, the large stones in the soil are removed or crushed so that the smaller particles heat up more easily and separate the pollutants from the material evenly. If the moisture of the material is too high, additional mechanical treatment may be required to improve the machining process.

The soil is fed to the rotary kiln on the mechanical weighing belt, the soil is moved down from the kiln by gravity. A specially designed flight system in the drum causes the grounds to fall directly into the center of the main burner flame. The flame located on the low side of the drum provides the heat absorbed by the soil. This heat causes volatile compounds to be released into the air stream and carried out of the furnace. Furnace temperatures can be controlled for optimum desorption efficiency depending on pollutant concentration and soil type.

Evaporated pollutants are sent to a bag filter to remove dust and then to the secondary oxidizer. The process gas stream from the bag is directed via its fan to a modular thermal oxidizer unit that reduces the hydrocarbon content of the gas stream with a destruction efficiency of up to 99.99% depending on the pollutant concentrations. At this stage, the clean soil material exiting the primary chamber of the TDU is rehydrated to 7% to 10% moisture and then cooled.

Combustion and Drying Systems we Manufacture

Hazardous Waste disposal incineration

Medical Waste disposal incineration

Animal Waste drying

Waste Water Sludge drying

oil sludge drying

Animal Manure Drying

Poultry Manure Drying

Pulp and Paper Drying

![]()

Phone: + 90 545 171 52 64

Phone: + 90 531 373 95 44

Phone: + 213 557 30 14 14

Phone: + 213 554 97 20 00

![]()

Turkey Address:Organize Sanayi Bölgesi Beyköy Beldesi İstiklal OSB 1 Mah. 5.Cad. D.Kapı No:67 Merkez / DÜZCE

fikricetinkaya@gmail.com

![]() 10 Rue 07 ilot 03 les patane blc:a2 appt 10 Ali mendjeli Constantine Algerie, 25000 Constantine, ALGERIA

10 Rue 07 ilot 03 les patane blc:a2 appt 10 Ali mendjeli Constantine Algerie, 25000 Constantine, ALGERIA

Email: info@sarltpmchan.com